In the last couple of decades, bagless vacuum cleaners have dominated both the public eye and store shelves, If you're shopping for a new vacuum cleaner in a big box store like Target or Wal-Mart, almost everything you see is going to be bagless. After all, bagless vacuum cleaners have a few nice things going for them: you don't have to buy or keep track of bags, and many of them are comparatively inexpensive. But despite the recent popularity of bagless vacuum cleaners, we're inclined to recommend bagged vacuum cleaners instead. A bagged vacuum cleaner is probably the better financial choice in the long run, and it'll leave your home and the air you breathe much cleaner than a bagless. A Cheap Vacuum Cleaner Might be Expensive in the Long Run Many people—especially young people who don't have much experience with buying appliances—look at the low prices of some bagless vacuum cleaners and make their choice right then and there. After all, if you're just trying to vacuum your floor, why pay hundreds of dollars when you can do it for less than $80? But that $80 vacuum cleaner isn't built like it's sturdier cousins. Most cheap, bagless vacuum cleaners are cheap for a reason. In order to drive the price down low enough to catch your eye, they've made as many parts as possible out of cheap plastic that's sure to break before long. And that's not the only corner that gets cut. By putting less effort into filtering dust out before it reaches the motor, they've ensured that the motor bearings will eventually go bad, weather it's from dirt and debris or accumulated moisture. As a result, inexpensive bagless vacuum cleaners often go bad in a handful of years, long before most bagged vacuum cleaners—and it takes a lot less to break them! Some machines are even glued together during manufacturing, mening that all it takes is an enthusiastic puppy chewing through your cord, and you'll have to start over. Over time, the cost of buying “cheap” vacuum cleaners over and over and over again will cost you as much as or more than what a higher-end vacuum would cost—and your floor will be less clean the whole time! Cleaner Carpets and Cleaner Air Most cheap, bagless vacuum cleaners aren't even getting the most out of the motors they have. Many of these vacuum cleaners have gaskets all over that are just plastic pressed into rubber, and the plastic housings warp easily. As a result, they're far from air tight. A lot of the suction that the motor provides is lost before it gets to your floor as it leaks from various cracks and crevices over the machine. Another consequnces of these loose fittings is poor filtration. Dust and dirt that you pick up from your floor will get thrown back into the air of your house before it ever gets to the container. Many of these machines have HEPA filters in them and claim to do an excellent job of filtering the dirt from the air, but that claim only applies to the dirt that makes it to the filter. Anything that leaks out beforehand isn't affected by the filter at all. A well-manufactured bagged vacuum cleaner is a closed circuit. With no need to seperate the dirt container, a much greater percentage of the air going in actually makes it through the whole system. Your vacuum's bag also acts as a filter in itself, ensuring that the air put back out by your machine is as clean as possible. The Winner is Clear If you want your house as clean as it can be, buy a bagged vacuum cleaner. If you want to buy an appliance that will last for years, buy a bagged vacuum cleaner! Small, bagless vacuum cleaners do have their place, but they're better used as a secondary machine used for cleaning up small messes and spills. If you want a machine that will be reliable and efficient, buying a bagged vacuum cleaner like a Simplicity or Riccar upright is a no-brainer. If you want to find the perfect vacuum cleaner for your home or business—or if you need your current one looked at—come and see us on the corner of 27th and Randolph Street in Lincoln, Nebraska or give us a call at (402) 438-3163

There's something inherent in human nature that makes us appreciate old things. Whether it's nostalgia for a period of our lives we remember fondly or a window into a time we never got to experience, our love for old things has fueled a thriving antiques industry all across the world. But while there may not be much of a practical advantage to using a set of antique dishes over a new set, oftentimes buying an older sewing machine is the most sensible thing to do. If you're in the market for a sewing machine, it might seem obvious to choose a shiny, brand-new machine over one that's half a century old. After all, the new machine might have a warranty, and it's sure to last longer for your money, right? Well, that's not always the case. We've been in the business of sewing machines repair and sales for over thirty years now, and we think that buying vintage sewing machines is usually a better investment than buying new. Let us tell you why. More Metal Parts We've talked before about the advantages of a metal-geared machine , and about how machines gained more and more plastic parts over time. And it's true--the newer your machine is, the more plastic it's likely to have in it. These days plastic is so common that you might have to special-order a machine to make sure it comes with metal gears! Having moving parts made of metal gives your machine a number of advantages. Most obviously, it's more durable. While a plastic-geared machine is likely to fail in a few years because of a broken tooth or just general wear, metal gears can hold up to exponentially more use and abuse. Even if a machine doesn't see a lot of use, plastic can grow brittle with time, and it's structure can be weakened just by sitting with the oil you use to keep your machine running well. Metal gears will also make your sewing machine sew smoothly. While plastic gears and frames can bend and flex under a little pressure, metal will hold strong. Metal gears are less likely to skip a tooth and leave your whole machine out of time, and have a smaller margin of error when making a stitch, so your machine will be able to handle more use and make cleaner stitches than it would with plastic parts. Tighter Engineering These days, we live in a disposable culture. When we buy an appliance, we expect to use it for a period of time until it stops working well, then throw it away and buy a replacement. It's how we've been doing things for a few decades now. But back in the first half of the 1900s, an appliance like a sewing machine was thought of as more of an investment. Just like you wouldn't be likely to throw your car away at the first sign of failure, people expected to buy a sewing machine and use it throughout their lives--with some repairs here and there if they were needed. And the machines were built to match this expectation. Older sewing machines are designed to run for years and years without needing work, and when they do fail, they're designed to be repaired. Newer machines are often just expected to outlast their warranty before they need to be replaced. And there's more than just reliability to gain. Because vintage sewing machines were a big expenditure, they have to have a performance to justify the cost. While many newer machines will cut corners to deliver an inexpensive product that does the bare-minimum, older machines have better feed mechanisms and cleaner stitches so whoever purchased them would be happy with their operation for years to come. A Better Bang for your Buck One reason why many people might hesitate to buy a vintage machine is because of how cheap many modern machines seem to be. After all, why would you spend $200 on a machine that's half a century old when you could buy a brand new one at the same price? But while the cost of a new machine may seem good up front, you'll be hard-pressed to find one at that price point that will live up to the reliability and performance of a good vintage machine at the same price. Spending $200-300 dollars on an old machine might seem steep for someone who's used to seeing $90 sewing machines on the shelves at a discount store, but compared to new machines in the same price range, you're getting a lot more value. While some particularly collectible machines might fetch higher prices, most vintage machines are being sold at a tiny fraction of their original cost when adjusted for inflation. And those machines were priced that way based on the quality of their materials and how effectively they operated--usually, higher priced modern machines still use cheaper materials, but the cost is justified by a large number of stitches or unnecessary computerized features. For the same price, you'll get much better performance from an older machine. Get Your Machines from a Reputable Source While the benefits of a vintage machine are obvious, it's not going to do you any good if the machine isn't in good condition! Most of these machines can be brought back to perfect working order with a little TLC, but if a machine has been sitting in disuse in someone's garage for decades, it's not going to work very well for you. When you buy a vintage sewing machine, make sure it's from a reputable source, and that it's been gone through from head to toe and restored to working order. While a machine from a stranger on Craigslist might seem like a great deal, chances are that they're getting rid of it for a reason--you're probably buying more of a headache than anything. We've been repairing sewing machines for more than thirty years now, and not only do we know which machines are worth reviving, we have the skills and expertise to make them sew like new. You can be confident that any machine you buy from us will perform like new--and that we'll be able to help with any problems if they arise. Vintage Sewing Machines are a Great Investment! All in all, a well-made, restored vintage sewing machine is probably going to be the best machine you can buy in your budget and despite their age, you'll be more likely to enjoy the machine for years to come. It's said about a lot of things, but it couldn't be more true about sewing machines: they just don't make them like they used to. If you're looking for a new sewing machine in your life, we sell some incredible vintage sewing machines on our Etsy page , as well as in our store at 2712 Randolph Street in Lincoln, Nebraska. Feel free to call us with any questions at (402) 438-3163. We'll be more than happy to find the perfect machine for you, or repair your older machine and keep it running long into the future!

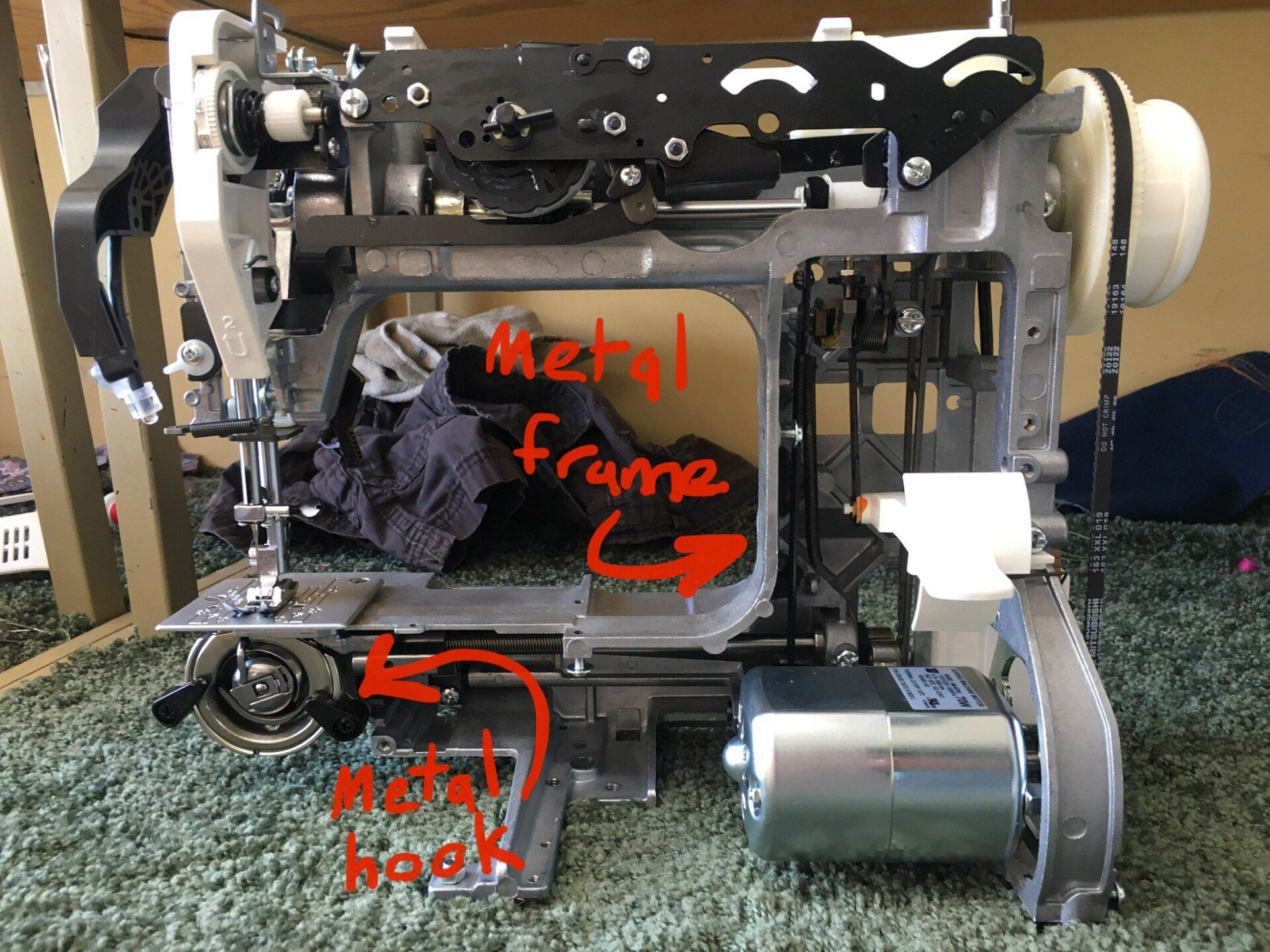

If you've ever picked up an old sewing machine, you probably immediately noticed a big difference between that old machine and one made in the last couple of decades--it's heavy! Old sewing machines were packed from head to toe with metal parts , giving them some significant heft. Thank goodness we have modern technology to make our new machines so much lighter, right? Well, not so much. As you might imagine, plastic parts may be lighter, but they're also much more susceptible to warping or breaking. That means the more plastic a machine has, the less likely it is to survive years of use. But that doesn't mean plastic is all bad either--when used in the right places, it can reduce the weight of the machine, or keep metal parts from rubbing on each other and causing wear. Some parts work very well when made from plastic, like bobbins or cams. While many machines sold these days are more plastic than not, the parts chosen and the reasoning behind them has changed as the years have gone by. With a little bit of history on why certain parts are made from plastic, and knowledge about which parts take well to plastic and which ones don't, you can make informed choices about the type of sewing machine you invest in. 1960s: The Dawn of Plastic Sewing machines in the 1960s had come a long way from their foot-propelled origins. Electronic and automated, the modern sewing machine was fast, reliable, and could be mass produced to meet the incredible demand of the public. But these machines had one downside when compared to their non-motorized predecessors: they made a racket. In order to try and cut down on the noise of grinding metal, manufacturers started putting nylon gears in some of their higher end machines. Initially seen as a huge step forward, the plastic gears weren't as loud, made the machine lighter and required less lubrication. While this seemed great when demonstrated in the store, the big downfall of the plastic parts wouldn't be seen until they had been put through hours of use. Lightweight, but Low Durability Despite the high price point of many of the plastic-geared machines, they didn't last anywhere near as long as their predecessors. While you could buy a metal-geared machine and expect it to last decades with a bit of maintenance, the plastic gears would lose teeth or wear down with use, meaning standard, everyday use would lead to major repairs. Gaps between worn teeth could turn even the most simple sewing tasks into an ordeal. You might even need to replace the machine entirely. Sewing machines made like this were far less likely to last long enough to be handed down from parent to child, and fewer of them survive in working condition today that the post-war machines that were built to last a lifetime. But despite the long-term problems these machines had, they had a huge benefit for the manufacturers: the plastic parts became cheaper to produce than the sturdier metal ones. The Rise of the "Cheap" Sewing Machine The 1980s saw a big boom in the now ubiquitous discount store. There was a huge demand for home products produced as quickly and cheaply as possible, all under the roof of the same store. More overseas manufacturing meant much stiffer competition with companies that could produce a machine at a fraction of the former cost--whether or not it would last. Consumers started to expect to buy their appliances for less than ever before, and sewing machines were no exception. In order to produce machines at a low enough cost be competitively priced, manufacturers began to cut costs wherever they could. Plastic frames, hooks, and more started to make their way into machines as more and more of the metal was pushed out. This had the added effect of making these machines lighter, which looked good to potential buyers comparing two machines in the store. Computerized Machines: Complex and Short-Lived With an onslaught of new brands and the changing face of the market, the long-term reputation some companies had for reliability started to mean less, and more than ever, machines were sold based solely on what they could do on the show floor. They average consumer had no way of knowing which machine would be easier to repair or which one would survive more years of use, so gimmicks became king. Any new feature you could demonstrate that other machines didn't have make it look that much better in the eyes of the end user. Computerized machines touted hundreds of stitches, automatic embroidery programs, and more, and the public embraced them wholeheartedly. The expectation of a sewing machine lasting a generation all but evaporated, so it didn't matter that these machines were difficult and expensive to repair, or that the technology that made them work would be quickly made obsolete. While these computerized features saw heavy use from a select few, many people who purchased these machines were left frustrated with a machine that could barely hem a pair of pants when technology moved on and the computerized features were no longer viable. Can I Still Buy a Metal Machine? Fortunately, well-built machines haven't completely disappeared from the market. Most manufacturers still make a model or two with metal gears designed for long-term use--even if you might have to jump through some hoops to get them. And many of those old, sturdy machines are still in circulation and will keep sewing beautifully for years to come, if they're taken care of. Many of them even cost much less than some of the more expensive computerized machines. A reliable sewing machine is still in reach if you shop carefully. We've been in the sewing machine repair business for more than thirty years, and we know what will last and what won't. If you're looking for a machine that will perform well and won't need to be replaced in a few years, we'll be more than happy to find one that perfectly fits your needs. Give us a call at (402) 438-3163, or stop on by our store at 2712 Randolph Street in Lincoln, NE. You deserve a machine that isn't going to be more of a headache than it's worth. If you're interested in seeing some vintage machines we have for sale, or just want to see some examples of how sewing machines have changed through the ages, take a look at our Etsy page !